Economic Survey Flags Chip Access as Key to India’s Strategic Autonomy

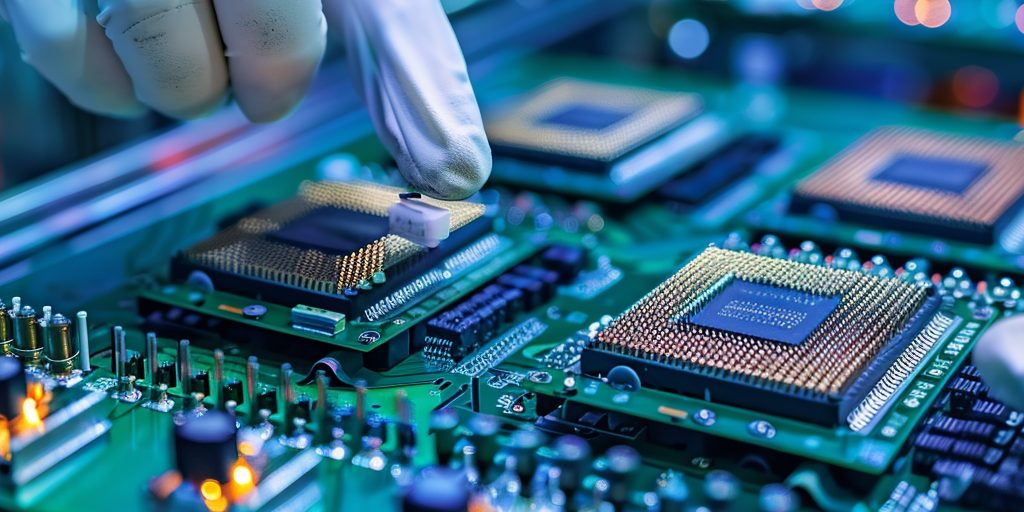

Access to semiconductors has emerged as a critical pillar of economic strength and strategic independence, according to the Economic Survey 2026, released on January 29. At a time when global trade is being reshaped by export controls and geopolitical shifts, countries without strong domestic chip capabilities face serious risks of supply disruptions and external dependence. The Survey highlights that semiconductors are no longer just commercial products but strategic assets that directly influence national security, industrial competitiveness and economic resilience across sectors.

To address these challenges, India has significantly scaled up its semiconductor ambitions through a ₹76,000-crore incentive framework under the India Semiconductor Mission and the Semicon India programme. The policy provides fiscal support of up to 50 per cent of project costs for semiconductor and display fabrication plants, compound semiconductor units, and assembly, testing, marking and packaging facilities. In parallel, the Design Linked Incentive scheme aims to build strong indigenous chip design capabilities, recognising that design leadership is central to long-term value creation in the semiconductor industry.

The Survey underlines the importance of microprocessors, which silently power vital systems such as power grids, telecom networks, financial markets, healthcare services and transport infrastructure. The COVID-19 pandemic exposed the fragility of global semiconductor supply chains, with shortages affecting over 169 industries worldwide, leading to production delays and rising costs. It also points out that semiconductor design is one of the most research-intensive industries, requiring advanced intellectual property, long-term research investment and a highly skilled workforce. Currently, nearly 80 per cent of global chip design revenues are concentrated in a few countries, including the US, South Korea, Taiwan and Japan.

Manufacturing barriers are even higher, with advanced fabrication plants costing around $10 billion and relying on highly specialised equipment supplied by a limited number of global firms. Against this backdrop, India is working to create an end-to-end semiconductor ecosystem. As of August 2025, ten semiconductor manufacturing and packaging projects across six states have been approved, with proposed investments of about ₹1.6 lakh crore. Supported by state-level incentives and infrastructure, these efforts are expected to strengthen supply chain resilience, reduce import dependence and position India as a credible player in the global semiconductor value chain.

Source: Moneycontrol