India’s Manufacturing Ecosystem Advancing toward Self-Reliance

In an era where technological advancements are redefining the global manufacturing landscape, industrial automation and digital manufacturing have emerged as critical enablers o1 e1ffciency, precision, and scalability.

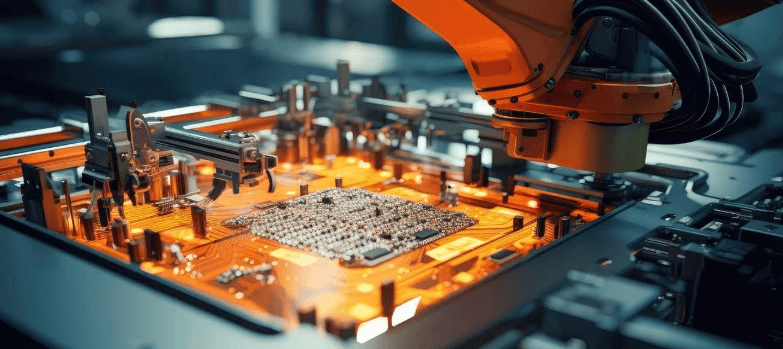

The electronics and semiconductor sectors, marked by their rapid growth and demand for high-volume production, are especially poised to benefit from these innovations. Industrial automation not only streamlines complex production processes but also enhances product quality and reduces operational costs, making it an indispensable component for manufacturers aiming to maintain a competitive edge in the market.

In an interview with IGNITO, Dilip Sawhney, Managing Director of Rockwell Automation India, shares his insights into the evolving role of automation and digital manufacturing in revolutionizing the electronics and semiconductor industries.

How do you see industrial automation transforming the global manufacturing landscape, especially in high-tech sectors like electronics and semiconductors? What key innovations or technologies are driving this transformation?

Sawhney: Industries like electronics and semiconductors are gaining even more centerstage as technology surrounds every aspect of our lives like never before. This trend places increasingly greater demands on these manufacturers to be more productive, innovative and resilient

Industrial automation is revolutionizing manufacturing, especially in high-tech sectors like electronics and semiconductors. By leveraging technologies such as AI, ML, the Industrial Internet of Things (IIoT), and Robotic Process Automation (RPA), manufacturers can achieve remarkable precision and efficiency. Machine learning enables real-time quality control and predictive maintenance, while IIoT sensors offer valuable insights into production variables, ensuring high yields and reducing waste. Collaborative robots (cobots) and RPA streamline operations, allowing human workers to focus on more strategic, high-value tasks. Embracing these advancements is crucial for remaining competitive in today’s dynamic market.

Digital Twin technology and Edge Computing are transforming manufacturing by enabling real-time simulation and data processing directly at production sites. This supports quick decision-making and allows for virtual testing of changes without disrupting operations.

The addition of 5G connectivity enhances this by providing seamless, high-speed communication essential in precision-driven environments. Advancements in Augmented Reality (AR) and Virtual Reality (VR) improve training and maintenance, reducing downtime and enhancing equipment handling.

These technologies promote sustainable practices by optimizing resource use, minimizing waste, and improving energy management. In high-tech industries, where small errors can lead to significant losses, automation ensures high quality, speeds up production, and allows quick design adaptations. Together, these advancements are setting a new benchmark for efficiency and innovation, helping manufacturers excel in a competitive global market.

How has the demand for automation in electronics and semiconductor manufacturing evolved in India, and what growth potential do you foresee in the near future?

Sawhney: The demand for automation in India’s electronics and semiconductor sectors is rapidly increasing, driven by the “Make in India” initiative and the push for self- reliance in semiconductors. As local demand for consumer electronics and smartphones rises, now is the time for India to enhance its manufacturing capabilities and strengthen its global position.

India’s electronics market is projected to reach $400 billion by 2025, driving manufacturers to adopt automation for improved quality and efficiency. The PLI scheme aims to attract $10 billion in investments for electronics and semiconductor manufacturing by 2026. The budget for semiconductor and display manufacturing has increased significantly—from INR 2,000 crores ($270 million) to INR 6,903 crores ($1 billion).

India’s manufacturing ecosystem, supported by government initiatives, is advancing toward self-reliance and technological innovation, strengthening the country’s position in the global high-tech manufacturing sector.

How is India positioned to become a leader in automated manufacturing for high-tech sectors?

Sawhney: India has undoubtedly emerged as a breakout leader in terms of its IT prowess as well as adoption of digital technologies at scale for societal good. This, along with the strategic nature of sectors like semiconductor, is supercharging the demand for manufacturing in these sectors in India.

The Indian manufacturing sector is rapidly embracing smart manufacturing technologies. This shift is enabling manufacturers to enhance automation, streamline processes, and achieve better business outcomes. As digital transformation takes centre stage, demand for automation, particularly in the electronics and semiconductor industries, is expected to rise significantly.

By 2025, the automation market in these sectors is projected to reach nearly $2 billion, growing at a CAGR of 18-20%. With a focus on building a robust semiconductor ecosystem, India is positioning itself as a strong competitor in global high-tech manufacturing. The Ministry of Information Technology estimates the semiconductor market could surpass $100 billion by 2030.

Initiatives like the PLI and DLI, along with tax breaks and eased regulations, are essential for supporting manufacturers. The government is also working to establish semiconductor fabrication plants, further enhancing the electronics manufacturing landscape.

Alongside investments and supportive policies, India’s digital infrastructure, huge domestic market, the shift in the global value chain, and the availability of large pool of skilled workforce will help India emerge as a leader in high-tech manufacturing.

As automation becomes more prevalent, how do you see the role of human workers evolving in the electronics and semiconductor manufacturing processes? What skills or training will be most crucial for the workforce?

Sawhney: As industrial automation transforms electronics and semiconductor manufacturing, human roles are shifting from routine tasks to essential management and problem- solving of automated systems. This change empowers workers to guide these systems effectively, enhancing productivity and precision.

To succeed, the workforce must grasp automation technologies like robotics, machine learning, and AI. Strong analytical skills are essential for interpreting the abundant data available. Familiarity with data analytics, basic coding, and tools such as Programmable Logic Controllers (PLCs) and Supervisory Control and Data Acquisition (SCADA) systems is crucial for effective troubleshooting and optimization.

The focus will increasingly shift towards high-level problem-solving, requiring strong critical thinking skills. Collaboration is vital in this automated environment. Working effectively with engineers, IT specialists, and data analysts will drive innovation and e1ffciency.

In what ways has the shift toward smart manufacturing and Industry 4.0 impacted productivity and efficiency in these sectors? How are companies adapting to this shift?

Sawhney: Smart manufacturing and Industry 4.0 are transforming productivity in the semiconductor and electronics industries through the integration of IoT, AI, robotics, and real-time analytics. AI-driven automation enhances precision, reduces defects, and increases yield while predicting failures to lower downtime and maintenance costs.

Real-time analytics streamline decision-making and eliminate bottlenecks, and robotics enable quick adjustments to shifting demands. Additionally, simulations optimize processes, reducing development time and costs. IoT and blockchain improve supply chain management with real-time tracking, enhancing inventory efficiency.

Manufacturers are shifting towards adoption of smart technologies. They are increasingly using cutting-edge technologies for more intelligent automation and to improve business outcomes, while driving simplification and gaining agility in their production operations.

What role do you see Rockwell Automation playing in the digitalization of manufacturing processes within the electronics and semiconductor industries? Can you share examples of successful implementations?

Sawhney: Rockwell Automation plays a significant role in the electronics and semiconductor sectors through its comprehensive portfolio of automation solutions and services.

- Advanced Automation Solutions: Rockwell offers integrated automation systems that combine hardware and software to enhance manufacturing efficiency and productivity. This includes PLCs, DCS and industrial PCs tailored for semiconductor and electronics manufacturing. Company provides robotics solutions that improve precision and speed in assembly, packaging, and material handling, crucial for high-tech manufacturing environments.

- Smart Manufacturing and Industry 4.0: Rockwell’s FactoryTalk software suite enables real-time data collection and analytics, helping manufacturers optimize operations and make data-driven decisions. This supports the transition to smart manufacturing. Rockwell’s digital twin solutions allow manufacturers to simulate and optimize their processes before implementation, reducing development time and costs.

- Ǫuality and Compliance: Rockwell provides tools for monitoring and ensuring product quality throughout the manufacturing process. This includes in-process quality checks and compliance with industry standards. Rockwell also facilitate traceability of components and materials, which is essential in industries like semiconductors where compliance and quality control are critical.

In addition, Rockwell provides cybersecurity, sustainability solutions, and training & support services to electronics manufacturers.

Looking ahead, what do you think the next five years hold for industrial automation and its impact on high- tech sectors like electronics and semiconductors? What role will Rockwell Automation play in shaping this future?

Sawhney: In the near future, industrial automation will transform high-tech sectors like electronics and semiconductors. By utilizing AI for predictive maintenance and quality control, companies can significantly reduce downtime and defects. IoT-based real-time data processing will enable manufacturers to quickly respond to changes, enhancing efficiency and decision-making.

The semiconductor industry is experiencing a remarkable transformation through advanced technologies. AI-driven production design and IoT-based control enhance e1ffciency, while autonomous logistics using automated mobile robots (AMRs) and collaborative robots (cobots) streamline operations. Integrated edge computing solutions further boost processing speed.

These innovations enable real-time monitoring and centralized data analysis, paving the way for fully autonomous operations that significantly improve productivity and efficiency.

As systems become more interconnected, strong cybersecurity measures will be essential for protecting sensitive data. Manufacturers will prioritize investments in technologies that enhance cyber resilience.

Sustainability will be a key focus, with the World Economic Forum noting that companies adopting sustainable practices can see profits increase by 15%. The shift will be toward automation solutions that reduce waste and energy use. And, the workforce will need new skills to operate advanced technologies, and investing in training can yield significant productivity gains.

Rockwell Automation is well positioned to lead this evolution by providing innovative solutions that improve efficiency, reduce costs, strengthen cybersecurity, and promote sustainability, helping manufacturers thrive in a fast-changing market.

hello!,I like your writing so much! share we communicate more about your article on AOL? I need an expert on this area to solve my problem. Maybe that’s you! Looking forward to see you.